News

What to do if the propeller of the charcoal machine equipment is worn? How to maintain the propeller of the charcoal machine?

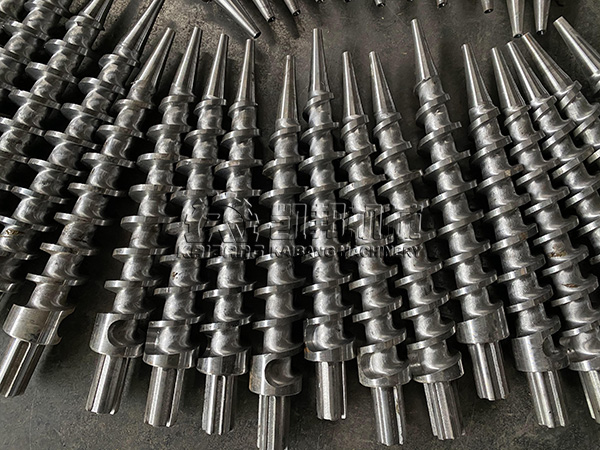

The Charcoal machine equipment is the main equipment for professional production of machine-made charcoal. There are many parts in the equipment, and the propeller is a consumable part in the charcoal machine equipment. Users need to pay more attention to the operation problems and repair them to ensure their production efficiency and effect. So what to do if the propeller of the charcoal machine equipment is worn? How to maintain the propeller of the charcoal machine?

What to do if the propeller of the charcoal machine equipment is worn?

The propeller wears very quickly during the production process of the charcoal machine equipment. The high temperature of several hundred degrees plus the pressure friction of more than 5 tons, even the strongest materials can't stand it for a long time. It's actually very simple to solve this problem. First of all, the raw materials must be ensured to be dry, so that the wear of the propeller is relatively small, and the particle size and impurity content of the sawdust have an impact on the wear degree. There is also the size of the motor. The motor that is too small will cause the propeller to wear faster because the power is not enough. When welding the propeller, it is better to choose high-carbon steel wear-resistant welding rods. Other welding rods wear faster and are not recommended. As long as the welding rod is wear-resistant and the welding technology is not very bad, there is generally no problem.

If you want to increase the service life of environmentally friendly charcoal machine equipment, that is, the service life of the accessory propeller, cone sleeve and forming cylinder. The simpler method is not to heat too fast. Some people directly adjust the temperature controller to more than 300 degrees when they start the machine. The temperature rises quickly and they can produce in ten minutes, but this is not good for the forming cylinder. The sudden temperature rise will soften the steel and accelerate the wear. The way is to adjust it to 100 degrees first, then heat it for a few minutes and then slowly heat it up. It will reach the predetermined temperature in thirty to forty minutes, which is better for the forming cylinder. The propeller of the charcoal machine equipment is an important part of the charcoal machine. Usually, problems will affect the entire mechanism charcoal production! It is particularly important to pay attention to the propeller of the rod making machine! It is an important part of the charcoal machine accessories.

Under normal use, the propeller of the charcoal machine equipment should generally be removed for repair after about 12 hours, but some raw materials have different textures and may need to be removed for repair in a shorter time (the wear resistance and heat resistance of the welding rod used during repair may also affect the use time). For the welding and grinding of the propeller, experienced charcoal factories should have their own set of techniques to make the propeller as useful as possible, but everyone has different techniques from others, which is the key to the rod making process. Therefore, the primary way to reduce the wear of the propeller and extend the life of the propeller is to pay attention to the use and maintenance of the charcoal machine equipment.

How to maintain the propeller of the charcoal machine?

1. The vulnerable parts of the new charcoal machine equipment are mainly the propeller part on the rod making machine, because the propeller part of the rod making machine belongs to the high-pressure forming part, which is seriously worn in daily production, and the propellers produced by various new charcoal machine factories are not nearly the same, with high technical difficulty, and it is also a very difficult accessory to configure, which needs to be customized by the charcoal machine equipment manufacturer. The propeller is an important part of the rod making machine, which is related to the pressing density of the firewood stick during the rod making process. Therefore, the shape of the produced sticks is observed on the propeller. The wrong angle or wear of the front end of the propeller will cause problems.

2. When the technicians come to the door for free technical training, they will give a detailed introduction to the propeller. Another vulnerable part is the cone sleeve. Generally, its life span is more than half a year. The cone sleeve should be selected as a high-quality accessory. The cone sleeve is embedded in the forming cylinder and is a tight fit. It is difficult to get it out. The solution is to weld a steel bar to the inner wall of the cone sleeve, then pour water, and use the principle of thermal expansion and contraction to tap it a few times to get it out.

3. Charcoal machine equipment As a forming equipment in the process of machine-made charcoal production, the rod-making machine is particularly important in the production of machine-made charcoal. The propeller is a vulnerable part in the rod-making machine. It is often worn in the production of machine-made charcoal. Therefore, we have to inspect and repair it. The inspection and maintenance time of the rod-making machine propeller is generally 15-20 shifts. If the frequency of use is too high in a certain period of time, it is recommended that you shorten the inspection and maintenance cycle for production. If there is a problem with the rod-making machine propeller, it is the problem of forming. The shape and density of the machine-made rod are affected, which also directly affects the sales of the finished machine-made charcoal.

4. Therefore, it is very necessary to inspect and maintain the propeller of the charcoal making machine. In addition, when repairing the propeller of the charcoal making machine, it is recommended that you choose wear-resistant welding rods to repair it, because the propeller is used to extrude materials to make it wear-resistant. After the repair, use gauze to polish it to make its surface smooth, so that the surface of the machine-made rods produced by it is also smooth.

The above is the solution to the problem of propeller wear of charcoal making equipment and the maintenance method of the propeller. Users can pay attention to these when operating the charcoal making equipment, and the propeller problems should be solved in time to avoid causing greater hidden dangers and making the charcoal making equipment unable to operate better.

RELATED NEWS

- Why is a sawdust drum dryer needed in the production of charcoal and biomass bri 2025-05-14

- How to choose the right carbonization furnace to benefit your charcoal business? 2025-04-16

- Factors affecting the price of charcoal machines 2025-03-24

- What kind of mechanism charcoal machine is environmentally friendly equipment? H 2025-02-18

- Why avoid overnight production of raw materials for charcoal making equipment? H 2025-01-10

CATEGORIES

LATEST NEWS

CONTACT US

Contact: +86 13849088788

Phone: 13849088788

E-mail: kaibangmachinery@gmail.com

Whatsapp:8613849088788

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road