Charcoal briguettes making machine

Charcoal briguettes making machine

Brand: KAIBANG

A charcoal ball press machine compresses diverse powdered materials—such as charcoal dust, coal powder, iron powder, and more—into spherical shapes like oval, egg-shaped, or square forms. It is widely applied in fuel production, boiler heating, cooking, barbecuing, and other fields. This equipment plays a vital role in charcoal, coal, and metallurgical industries, distinguished by its efficiency and adaptability.

The charcoal briguettes making machine is a highly efficient forming equipment that can compress the carbon powder of biomass materials such as sawdust, coconut shells, straw, etc. after high-temperature pyrolysis and carbonization into high-density solid fuel balls. The equipment is equipped with a modular mold system, which can flexibly produce charcoal balls of various specifications such as cylindrical and hexagonal shapes to meet the needs of different application scenarios. The finished charcoal balls have a dense structure and stable combustion. They have the advantages of fast ignition, high calorific value, long storage, and easy transportation. They are widely used in various fields and are an ideal choice for the efficient utilization of biomass resources.

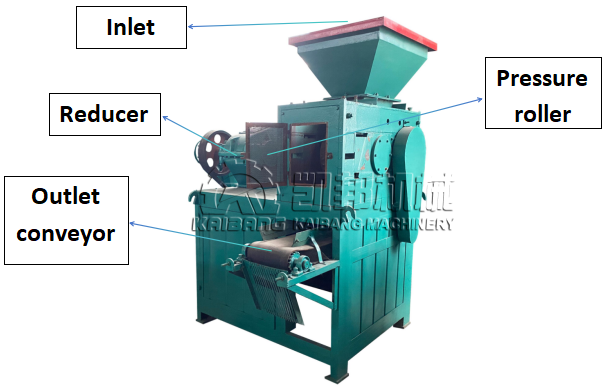

Charcoal powder briquette making machine is made up of three parts: feeding, driving and briquetting.

1. Feed section: To make sure materials enter double rollers evenly by feeding in ration. Driven by the electromagnetic speed regulating motor and after the belt wheel and worm reducer turn, the spiral feed device of briquette machines presses materials into the main feed port. As the constant matrix feature of the electromagnetic speed regulating motor, when the spiral feeder has the same pressing quantity with the inventory of the main body of the briquetting machine or briquettes machine, the feeding pressure will stay constant thus stabilizing the balling quality. If there is a large feed amount, the electricity of the feeding device will be overloaded and vice versa. Therefore, it's very important to operate the machine skillfully.

2. Driving section: The driving system consists of electromotor, triangle section, reducer, open gear and rollers. The briquetting machine runs relying on the cooperation of driving and driven shaft supported by the exposed gear. It is driven by the electromagnetic speed regulating motor; after the belt wheel and cylindrical gear reducer, the power is transferred to the pin coupling shaft. Hydraulic pressure device is installed on the back of the driven shaft block. The hydraulic protection device of briquette machine can make axial displacement of the piston as the hydraulic pump pushes the high pressure oil into the hydraulic tank. The front connecting end of the piston supports the bearing pedestal to meet the production requirement.

3. Briquetting section: Referring to the main body of the briquetting machine or briquette machine with the rollers as its core working part. When too many materials or metal blocks enter the space between the two compression rollers, the piston rod of the hydraulic cylinder gets so pressed that the pump will stop working and the energy accumulator will make buffer action facing pressure changing. Then the flood valve starts the oil return and the piston rod replacement will widen the space between the rollers thus forcing hard materials to pass the rollers. Finally, the whole pressure system of briquette machine or briquette press machine returns to normal condition so that the rollers won't be damaged.

Note: the briquettes shape and size are defined by customers.

a) Particle Size Specifications:

Particles smaller than 1mm: 30-40% proportion.

Particles between 1-2mm: 30-40% proportion.

Maximum particle size ≤3mm, with proportion ≤20%.

b) Moisture Content Requirements:

Material moisture must be maintained at 8-12% to ensure molding efficiency and equipment functionality.

c) Prohibited Materials:

Do NOT mix sieve fragments, hard block debris, or impurities into the material to avoid damaging rollers/main shafts and reducing equipment lifespan.

d) Binder/Additive Guidelines:

Users should prepare suitable binders or additives based on coal type and application environment to guarantee briquette quality and performance.

What can the charcoal briquette machine bring to you?

Biomass raw materials or sewage sludge can be converted into high-value charcoal powder after pyrolysis and carbonization. Through the KAIBANG charcoal briquette machine production line, these charcoal powders will be efficiently processed into high-value-added shaped charcoal products. KAIBANG MACHINERY welcomes your purchase at any time. You will get:

1. Flexible and customized production line solutions

We provide modular production line configurations, support personalized mold customization, and can accurately control the size and shape of charcoal balls to ensure that you can continuously and stably produce high-quality charcoal balls to meet the stringent requirements of various application scenarios.

2. Diversified product forms to seize market segments

The production line can produce a variety of professional-grade charcoal products: hookah block charcoal, pillow charcoal, cylindrical charcoal, hexagonal charcoal, square charcoal, round hookah charcoal, etc. This product diversification can meet different market needs and preferences and expand your potential customer base.

3. High-profit business model

You can sell charcoal balls to different customer groups according to the different uses of charcoal, thereby making a lucrative profit. For example, you can sell it to industrial fuel users, or users who are interested in investing in barbecue charcoal or hookah charcoal. You can also serve customers engaged in carbon sequestration, carbon credits, and biochar animal feed. Or, you can sell it to users who want to use charcoal as a reducing agent for metal smelting.

Kaibang machinery provides you with a full chain of services from equipment selection to market analysis to help you quickly realize a return on investment. Contact us now to get exclusive production line solutions and industry profit analysis reports!

Why do we compress charcoal into briquettes?

Why do we process biomass raw materials into charcoal blocks instead of burning them directly for energy? In fact, there are many problems with directly burning raw biomass, including low energy utilization, high pollution emissions, incomplete combustion (producing a lot of smoke and odor), and unstable calorific value. The shaped charcoal prepared by the KAIBANG charcoal block machine can effectively solve these problems. The charcoal blocks produced have many advantages, including:

High thermal efficiency: The high-temperature pyrolysis process effectively removes moisture and volatiles from the raw materials, and then the high-pressure molding significantly increases the density of the charcoal blocks, thereby increasing the calorific value of the charcoal blocks.

Easy to transport, store and use: Charcoal briquettes are compact in shape, uniform in size, and low in moisture content, making them easy to transport, store and use. This brings convenience to consumers and retailers.

Clean combustion: High-temperature pyrolysis removes most of the volatile substances and impurities in the raw materials. Therefore, charcoal produces less smoke, ash and harmful emissions when it burns.

Wide range of uses: Charcoal blocks can be customized by adjusting additives or shapes to meet specific uses. For example, giving hookah charcoal better flavor, faster ignition speed and longer burning time.

Although the ball making process is simple, the ball making machine has very strict requirements on materials:

Biomass raw materials cannot be directly fed into the Sawdust Briquette Machine. They must be carbonized first and then ground into powder.

The particle size of the powdered material is controlled within 8mm. The smaller the particle size, the easier it is to form.

The moisture content of the powder can be dried to 5-10%. It is not easy to form a ball if it is too wet or too dry.

Do not mix iron blocks or blocky debris with high hardness into the powder to avoid damaging the roller and shaft.

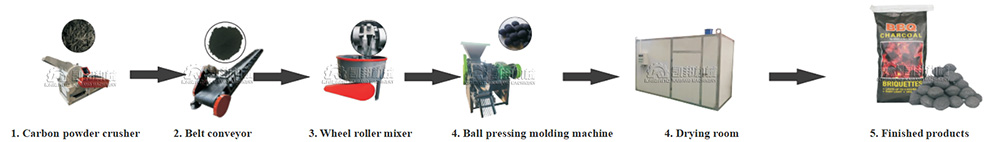

If your raw materials are sawdust, rice husks, or coconut shells, we recommend processing them into charcoal using our carbonization furnace. This converts organic waste into high-quality charcoal feedstock for subsequent production stages.

The carbonized charcoal is then crushed into fine powder using a grinder. This ensures uniform particle distribution, facilitating efficient mixing and shaping in later steps.

Use a charcoal mixer to thoroughly combine the powdered charcoal with binder. Proper mixing guarantees homogeneous consistency, which directly enhances the strength and integrity of the final briquettes.

Mix starch and water in precise proportions using a stirrer until a lump-free, smooth solution forms. This creates an effective binder solution ready for application.

Finally, our briquette machine compresses the mixed material into customizable shapes based on your specific needs, accommodating diverse industrial or domestic applications.

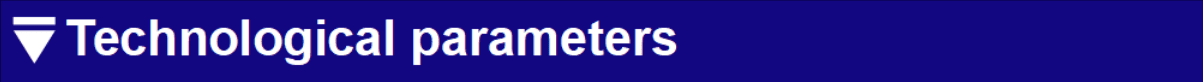

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy. >

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: +86 13849088788

Phone: 13849088788

E-mail: kaibangmachinery@gmail.com

Whatsapp:8613849088788

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road