News

Relevant factors of calorific value of charcoal produced by machine-made charcoal machine

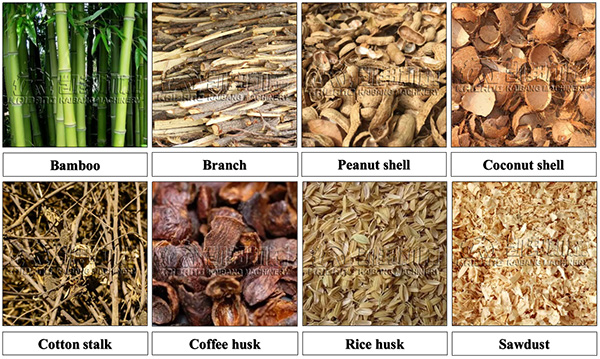

Mechanical Charcoal machine, also known as charcoal machine equipment, is a professional charcoal machine used to make new fuel. This product can replace coal, effectively alleviate the energy crisis, turn waste into treasure, and increase investor income. The biomass charcoal energy of machine-made charcoal machine uses agricultural and forestry waste (such as sawdust, wood chips, rice husks, peanut shells, sunflower seed shells, coconut shells, trees, wood chips, sugarcane bagasse, furniture factory scraps, etc.) as raw materials without any additives. After crushing, drying, rod making, carbonization and other processes, it is made into machine-made charcoal.

The calorific value of machine-made charcoal has no direct relationship with the fuel time. Generally, the carbon content of charcoal determines the calorific value. The higher the carbon content of charcoal, the greater the calorific value is generally. This is determined by two factors: raw materials and carbonization degree. It can also be said that it is determined by the chemical composition of charcoal. The burning time can be said to be determined by chemical and physical factors. It is not only about high calorific value, but also requires that the surface area of charcoal in contact with air should be small to extend the burning time. This surface area includes both the outer surface and the internal pores. Because there are many gaps inside the original charcoal, although the calorific value is comparable to that of machine-made charcoal, it does not burn as long as machine-made charcoal. There are two main ways to increase the burning time of machine-made charcoal. One is to increase the molding pressure of the rod-making machine to increase the density and strength of the rod. The second is to increase the final carbonization temperature of the kiln and slow down the speed of heating and cooling, so that the finished product has high density and high hardness. These two points are also the main ways to improve the quality and price of machine-made charcoal.

In addition, paying more attention to the following points during the operation of the charcoal machine equipment can ensure your worry-free operation:

1. Rod-making machine maintenance: eliminate all problems in rod making, including welding and grinding shafts, to achieve first-class rod making.

2. Improvement of dryer: Is your dryer too slow in wind speed, can’t dry, has jets coming out of the discharge port, and can’t work normally? Through our improvement of dryer, we can increase wind speed and no longer spray out the discharge port.

3. Training of carbonization technology: Whether it is earth kiln or car kiln, we can use professional carbonization technology to carbonize high-quality machine-made charcoal, and our carbonization technology is ahead of our peers.

4. Elimination of comprehensive problems of machine-made charcoal: Too much soil in the raw materials will result in high ash content and low heat. Carbonization broken sticks, broken and destructive cracks, smoke and smell, which lead to the charcoal not being sold at a high price. We can teach you how to eliminate the problems in the charcoal making process.

RELATED NEWS

- Why is a sawdust drum dryer needed in the production of charcoal and biomass bri 2025-05-14

- How to choose the right carbonization furnace to benefit your charcoal business? 2025-04-16

- Factors affecting the price of charcoal machines 2025-03-24

- What kind of mechanism charcoal machine is environmentally friendly equipment? H 2025-02-18

- Why avoid overnight production of raw materials for charcoal making equipment? H 2025-01-10

CATEGORIES

LATEST NEWS

CONTACT US

Contact: +86 13849088788

Phone: 13849088788

E-mail: kaibangmachinery@gmail.com

Whatsapp:8613849088788

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road