News

There are many kinds of raw materials for charcoal making. Which one is more suitable for charcoal making?

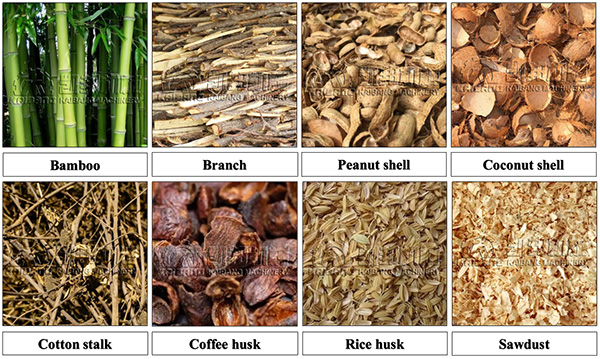

Charcoal making machine is a professional equipment for making mechanism charcoal. The equipment has many kinds of raw materials. The following is an analysis and summary of the raw materials for charcoal making by Kaibang charcoal making machine manufacturer. Let's see which raw materials are more suitable for making mechanism charcoal.

1. Hard miscellaneous wood. There are many kinds of hard miscellaneous wood, such as birch, basswood, elm, green dry willow, most fruit trees and various bamboos in the south can be classified into this category. Its growth years are generally between pine and cork, and the wood is harder. Most of them can be used as raw materials for mechanism charcoal. However, due to the obvious differences in its composition characteristics, it often encounters many difficulties when it is used as raw material for production. One of the obvious problems is weak adhesion. For some of the raw materials, simply mixing with other wood raw materials can no longer solve the problem. The technical requirements for using hard miscellaneous wood for production are very high.

2. Crop waste. Some woody crop waste can be used as raw materials for machine-made charcoal, but they generally have weaknesses such as high ash content and low calorific value. In addition, it is difficult to form, requiring very high forming temperature and extrusion pressure, and high technical requirements. However, if there is no ideal firewood charcoal raw material in your area within a considerable range, and the market demand for machine-made charcoal is very large, and you need to purchase it from other places, you can also consider using agricultural waste for production. The advantages of this production are that the raw materials are sufficient and easy to obtain, and the cost is low. For example, a considerable number of barbecue restaurants buy machine-made charcoal not to use it to grill food, but to use its long burning time to continue the fire, so that guests can quickly start a fire for grilling when they come during non-meal time.

3. Larch. This is currently recognized as the most ideal raw material for machine-made charcoal. Because larch has a moderate lignin content and compact fiber knots and good density, it can form a high-density and hardness molded rod at a lower molding temperature and a smaller extrusion pressure.

4. Pine. Almost all pine wood is suitable for making machine-made charcoal. However, due to the differences in the nature of the ingredients, we will also encounter different problems in production. For example, the fiber knots of some pine woods are not ideal, making it difficult to form, which is a problem for some manufacturers. For example, once the fiber knots of white pine are destroyed, it is difficult to recover, and it is difficult to get a good machine-made rod even at a higher molding temperature and extrusion pressure. This requires us to mix other raw materials to improve its bonding ability. In addition, the density of some pine woods is not very ideal, such as camphor pine. Although it belongs to the pine wood and has a long growth cycle, the wood is still soft, which makes us often have insufficient feed when processing this raw material, resulting in cracks in the molded rod. In response to this situation, the propeller's spiral pitch or the spiral diameter can be appropriately adjusted to overcome it. Due to the different growth regions and growth cycles, the component proportions and structural characteristics of various pine woods are different, but if we can make a reasonable and accurate analysis of these and take appropriate measures, pine wood is still a very ideal raw material.

In short, there are many tree species that can be used to make machine-made charcoal, but the ash content of machine-made charcoal made from tree species with relatively soft materials is relatively large. Choosing the right raw materials for making machine-made charcoal will bring you considerable income.

RELATED NEWS

- Why is a sawdust drum dryer needed in the production of charcoal and biomass bri 2025-05-14

- How to choose the right carbonization furnace to benefit your charcoal business? 2025-04-16

- Factors affecting the price of charcoal machines 2025-03-24

- What kind of mechanism charcoal machine is environmentally friendly equipment? H 2025-02-18

- Why avoid overnight production of raw materials for charcoal making equipment? H 2025-01-10

CATEGORIES

LATEST NEWS

CONTACT US

Contact: +86 13849088788

Phone: 13849088788

E-mail: kaibangmachinery@gmail.com

Whatsapp:8613849088788

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road