News

Correct operation of charcoal machine equipment to extend its service life

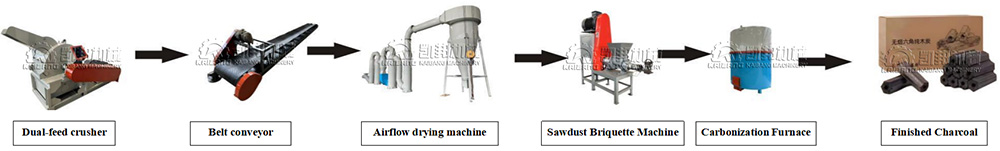

In today's new era of environmental protection and energy saving, machine-made Charcoal machine equipment is popular all over the world. Many entrepreneurs choose to invest in machine-made charcoal machines. Some impatient customers directly use raw materials to process charcoal after buying the equipment and arriving at the destination, and quickly enter the production state. Kaibang charcoal machine manufacturers remind everyone that it is wrong to do so. Blindly put into production without being familiar with the equipment, so that failures that would not have occurred are easy to occur, and it will also cause unnecessary losses to users. Therefore, Kaibang charcoal machine manufacturers have summarized some methods for the correct use of new machine debugging to help new customers extend the service life of charcoal machines.

Correct startup and debugging methods for new machines:

1. Ensure that all the connecting screws of the charcoal forming machine are connected and tightened, especially the three tops in the heating cylinder, which must be tightened.

2. After ensuring that the equipment is installed stably, all lubrication parts of equipment such as briquette machines, wood chip crushers, and airflow dryers need to be checked and gear oil added to ensure smooth operation of the equipment.

3. Connect the power supply of the main control box and install the standard safety wiring. Do not start the machine rashly at this time. You can start it for three to five minutes to see if there are any abnormal phenomena such as card or collision. If not, it can be put into production normally. Once the above situation occurs, you need to stop the machine immediately for inspection to completely eliminate the fault.

4. The new machine needs to ensure that the equipment heats up slowly. After the temperature rises, you can start the machine and feed the material into it.

5. In the process of feeding, remember not to be too fast. When the charcoal molding machine equipment works normally for 30 minutes, it can be turned off. At this time, it means that the test run has been successful and normal production can be carried out.

RELATED NEWS

- Why is a sawdust drum dryer needed in the production of charcoal and biomass bri 2025-05-14

- How to choose the right carbonization furnace to benefit your charcoal business? 2025-04-16

- Factors affecting the price of charcoal machines 2025-03-24

- What kind of mechanism charcoal machine is environmentally friendly equipment? H 2025-02-18

- Why avoid overnight production of raw materials for charcoal making equipment? H 2025-01-10

CATEGORIES

LATEST NEWS

CONTACT US

Contact: +86 13849088788

Phone: 13849088788

E-mail: kaibangmachinery@gmail.com

Whatsapp:8613849088788

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road