News

Kaibang charcoal machine manufacturer provides equipment production operation process for reference

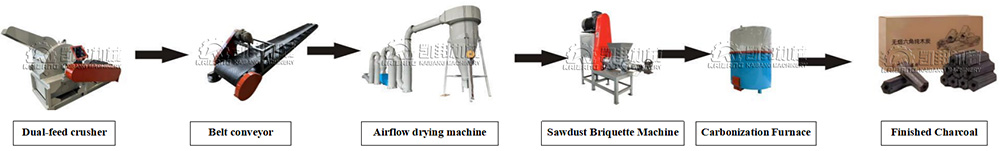

Since the Charcoal machine equipment was launched on the market, it has received a good response and attracted a large number of investors to invest in the industry. As a predecessor, Kaibang charcoal machine manufacturer briefly introduces the charcoal machine production operation process for reference. The production process of charcoal machine production includes raw material selection, drying and stick making, and carbonization.

1. Raw material selection: The selection of raw materials is an important indicator for making machine-made charcoal.

As we all know, the plant kingdom can be divided into perennial woody plants and annual herbaceous plants. In principle, woody plants are the best raw materials for making machine-made charcoal. It can produce high-quality charcoal with a low ash content of 4%, a high fixed carbon content of 80%, and a calorific value of 7500 kcal/kg. The market price is between 1800 yuan/piece and 2000 yuan/piece. The charcoal produced by herbaceous plants has an ash content of about 20% higher, a fixed carbon content of 60%, and a calorific value of 5000 kcal/kg. It can only be used as heating charcoal and has poor market sales.

2. Drying and rod making:After the raw materials enter the factory, they can be screened and dried to produce raw material rods. Drying is the key before forming rods. The moisture content of drying must be reduced to between 12% and 6% before rods can be made. This is very important for the selection of dryers, and the requirements are high. The raw materials with a moisture content of 35% are dried to about 10% at a time. For beginners, they often fall into a misunderstanding that the molding machine cannot be formed. The cracks, weight, and density of the raw material rods after molding are small, and they will be mistaken for the molding machine. The role of the dryer is ignored. Whether the moisture content of the raw materials is qualified is closely related to the quality of molding. Drying is the premise, and molding is the latter. Therefore, the drying index determines the molding and quality, which is relatively important.

3. Carbonization method: earth kiln, spontaneous combustion method, dry distillation method:

(1)Earth kiln: Advantages Earth kiln carbonization can ensure the amount of carbon. Disadvantages It takes a long time, 5 to 7 days. There is a lot of smoke during carbonization. At present, most areas have high environmental protection requirements and greater production difficulties.

(2)Spontaneous combustion method: At present, most square kilns produced by manufacturers use the spontaneous combustion method, which relies on the fuel rods to generate heat to carbonize themselves. It is actually oxygen-deficient combustion, there are dead corners during carbonization, and the carbonization temperature is generally 400 degrees. The yield is low.

RELATED NEWS

- Why is a sawdust drum dryer needed in the production of charcoal and biomass bri 2025-05-14

- How to choose the right carbonization furnace to benefit your charcoal business? 2025-04-16

- Factors affecting the price of charcoal machines 2025-03-24

- What kind of mechanism charcoal machine is environmentally friendly equipment? H 2025-02-18

- Why avoid overnight production of raw materials for charcoal making equipment? H 2025-01-10

CATEGORIES

LATEST NEWS

CONTACT US

Contact: +86 13849088788

Phone: 13849088788

E-mail: kaibangmachinery@gmail.com

Whatsapp:8613849088788

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road