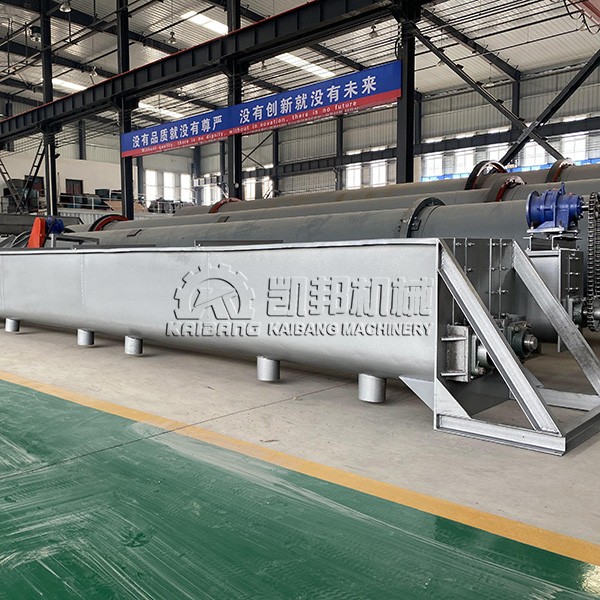

Double screw conveyor

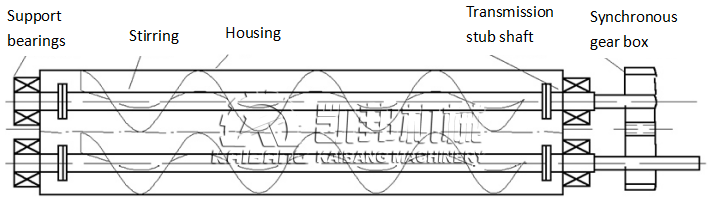

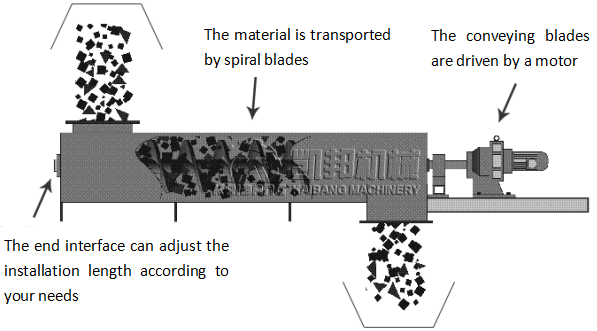

Introduction: The double screw conveyor consists of two screw shafts, the two screws rotate in opposite directions, the material is not easy to be blocked, and it has the function of crushing and mixing, and the conveying capacity is large.

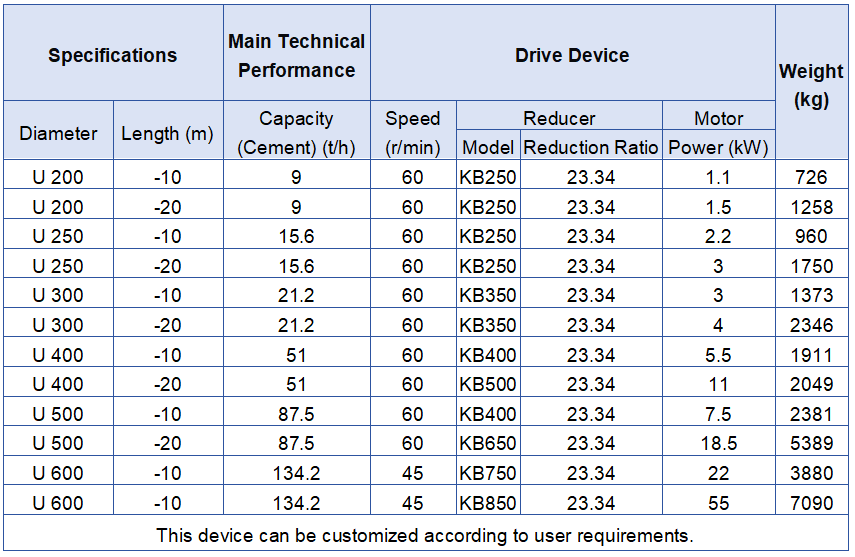

Length: 60 meters

Conveying capacity: 458 cubic meters/hour

Power: 1.1-24.4 kilowatts

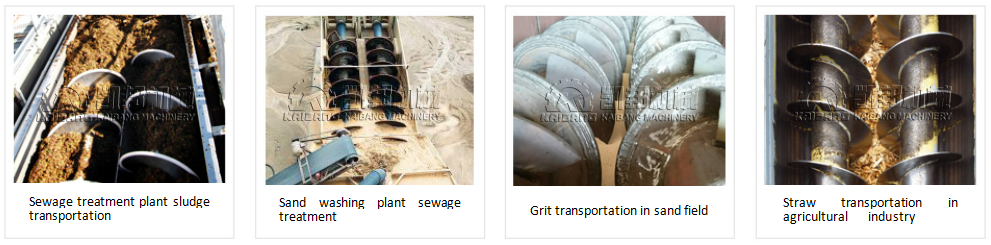

Applicable materials: Suitable for conveying materials with poor flow performance, large volume or size, and need to be stirred, such as straw, wood chips, sawdust, bran, paper, etc.

Application area: Usually works horizontally, suitable for feeding under the silo.

Product customization: material (carbon steel or stainless steel), trough width, inlet and outlet distance, feed port size, feed port number, etc. (customized on demand)

Double screw conveyor is also called double auger conveyor. As the name implies, it refers to a double-axis conveying equipment. In terms of appearance, it can be made into "U-shaped double-axis screw conveyor and double-tube auger conveyor". The conveying distance of the double screw conveyor ranges from 2 meters to 80 meters. The applicable occasions are the same as those of the single-axis screw conveyor. The main feature is the large conveying capacity and the ability to convey two production lines at the same time. It can realize multi-point unloading and multi-point feeding. The double screw conveyor is a continuous conveying equipment widely used in metallurgy, building materials, chemical industry, food and mechanical processing.

1. The two spiral blades rotate in opposite directions, one is left-handed and the other is right-handed, which can avoid the raw material from getting stuck in the spiral body. It is suitable for materials with large volume, poor fluidity or materials that need to be stirred.

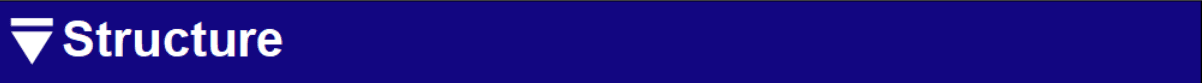

2. The spiral shaft and the hanging bearing, head and tail shaft are connected by embedded tongue type. Installation and disassembly do not require axial movement, which is convenient for maintenance. The core shaft is long, there are fewer hangings and fewer fault points.

3. The variable diameter structure is adopted to increase the volume at the hanging bearing to avoid contact between the hanging bearing and the raw material.

4. All transmission parts adopt floating connection mode, and the hanging bearing is a universal structure, so that the spiral body, hanging bearing and tail always form an integral rotating floating body, which can freely rotate and avoid the conveying resistance within a certain range, without jamming or blocking the material.

4. Compared with other conveying equipment, it has the advantages of small cross-sectional size of the whole machine, good sealing performance, stable and reliable operation, multi-point loading and unloading in the middle, safe operation, and simple maintenance.

5. The length can be customized and processed according to customer requirements, ranging from 2 meters to 70 meters, and the appearance is U-shaped.

Drive device: Suitable for outdoor use requirements, the motor reduction device adopts the structure of shaft-mounted reducer, the reduction transmission device is a helical gear or a combination of helical gear and worm gear transmission structure, and the reducer output shaft adopts a compound three-lip seal to avoid oil leakage. The reducer is equipped with an automatic oil level adjustment device to ensure that the gear transmission can achieve good lubrication under any temperature change conditions. The reduction device uses low-noise, high-efficiency and well-sealed products.

Drive motor: It is a flange-mounted asynchronous induction motor, suitable for power supply 380V, 3 phases, 60Hz, the motor is IP54 protected, and the speed is not more than 1500r/min.

Spiral: The spiral blade has sufficient strength and rigidity. ,

Support frame and conveying trough: The conveyor support frame is made of stainless steel profiles and fixed to the concrete civil foundation with stainless steel expansion bolts. The conveyor trough is 3.0mm thick and made into a U-shaped section. Except for the open feed port, the rest of the spiral trough is closed with a flat cover. The conveying trough and cover are all made of stainless steel.

The principle of the double-axis screw conveyor is that a solid screw is installed in each of the two seamless steel pipes, one of which is left-handed and the other is right-handed. When working, the two screws rotate through a pair of gears at the shaft extension position. Due to the rotation of the screw body, the material moves axially, thereby achieving the purpose of conveying.

The material is added from the feed port. When the shaft rotates, the material is affected by the normal thrust of the spiral blade. The radial component of the thrust and the friction of the blade on the material may cause the material to rotate around the axis, but due to the gravity of the material itself and the friction of the trough on the material, it does not rotate with the spiral blade, but moves along the axial direction of the trough under the action of the axial component of the normal thrust of the blade.

1. The two spiral blades rotate in opposite directions, one is left-handed and the other is right-handed, which can prevent the material from getting stuck in the spiral body.

2. While conveying materials, it also has mixing and stirring functions.

3. Since the double spiral shafts rotate at the same time, the double screw conveyor has a higher conveying capacity. It can handle a large amount of materials and realize a continuous conveying process, which is suitable for application scenarios requiring high output.

4. The double-axis structure allows the material to be evenly loaded on the two spiral shafts. Each spiral shaft bears part of the material's pushing work, which reduces the load on a single spiral shaft, reduces the operating pressure of the equipment, and increases the service life of the equipment.

5. Strong adaptability. The double-axis structure makes the double screw conveyor more adaptable. The two spiral shafts can adjust the rotation speed and direction relatively independently to meet the conveying needs of different materials. This flexibility makes the double screw conveyor suitable for handling a variety of materials, from fine particles to viscous materials, which can be effectively conveyed.

Double screw conveyor is suitable for materials that need to be stirred, powders, granules and small pieces with poor fluidity. It is used to handle non-homogeneous materials (wood chips, paper, etc.), materials in the flour processing industry (bran, flour, etc.) and bridging materials (such as sawdust, soybeans, etc.).

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy. >

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: +86 13849088788

Phone: 13849088788

E-mail: kaibangmachinery@gmail.com

Whatsapp:8613849088788

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road