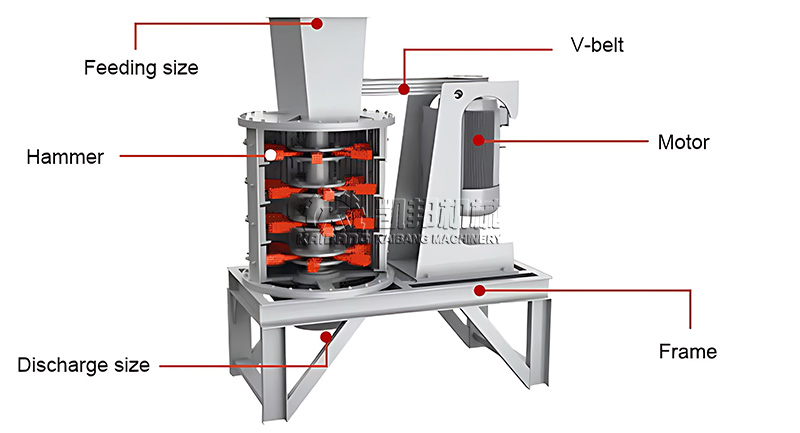

Vertical Compound Sand Making Machine

Feeding Size:<190mm

Capacity(t/h):10-20 t/h

Place of Origin:Henan, China

Weight:3000 KG

Application:Crushing plant, sand making plant

The compound crusher can crush large pieces of materials, and the discharging particle size can be adjusted arbitrarily. It is not affected by the wear of the hammer and liner. It adopts a screen-free structure and is not easy to be blocked. It is suitable for crushing materials with high moisture content and high mud content.

The working principle of vertical charcoal powder crusher is to crush the material by the impact of the moving hammer plate and the fixed anvil. Charcoal particles are fed into the machine through the hopper and fall on the coupling disc rotating at a high speed. Then, the particles are crushed by the hammer plate rotating around the disc and the particles are crushed into fine powder. The powder is then collected in the dust collection system.

Easy to operate, easy to maintain, low power consumption, high efficiency, and can be installed and lifted. It is an ideal product in crushing equipment. In various industries.

Functional characteristics of vertical pulverized coal machine

Vertical pulverized coal machine is a commonly used coal pulverization equipment, mainly used for coal pulverization, coal selection and crushing operations. Its main functional characteristics are as follows:

1. Highly automated: Vertical pulverized coal machine is a highly automated, easy-to-use equipment that can be widely used in the coal crushing industry.

2. High efficiency: Vertical pulverized coal machine can quickly crush large pieces of coal into powder, greatly improving work efficiency.

3. Energy saving and environmental protection: Vertical pulverized coal machine adopts high-efficiency energy-saving technology, which can effectively reduce energy consumption and will not pollute the environment.

4. Compact structure: Vertical pulverized coal machine has a compact structure, occupies a small space, and is suitable for various coal crushing occasions.

5. Long service life: Vertical coal crusher is made of high-quality materials, with the characteristics of long service life, wear resistance and corrosion resistance.

What are the benefits of using a charcoal vertical crusher?

1. Increase powder output: The vertical charcoal powder crusher is efficient and fast, and can quickly crush materials such as charcoal into powder, thereby greatly improving production efficiency and powder output.

2. Save costs: Compared with traditional crushing methods (such as manual crushing or mechanical crushing), the vertical charcoal powder crusher has a lower cost and can save a lot of manpower and material resources.

3. Protect the environment: The vertical charcoal powder crusher is made of environmentally friendly materials and will not cause any pollution to the environment. At the same time, the crushed charcoal or coal can also be better used in the manufacture of other products.

4. Convenient maintenance: The machine is simple to promote, easy to operate, and maintenance will not cause any trouble.

The application range of coal crusher is very wide, it can be used in coal crushing, coal processing, construction, roads, bridges, hydropower station construction and other fields. The raw materials used are mainly coal, limestone, granite, quartz stone, iron ore, metal ore, etc.

How to choose a suitable machine?

1. Choose a crusher with appropriate toughness and moderate rigidity according to production needs.

2. Choose a machine according to the power, processing capacity and processing efficiency of the equipment.

3. It is necessary to understand the reliability, structure, maintenance cost and service life of the machine.

4. Choose a suitable machine according to technical performance indicators such as power, efficiency, speed, etc.

<Note: With continuous technological upgrades, all parameters are provided for reference only. In case of any modifications, please refer to the actual product for accuracy. >

Henan Kaibang Machinery Manufacturing Co., Ltd. mainly produces: crushing equipment, drying equipment, forming equipment, pyrolysis reactor equipment, environmental protection equipment, and other complete production line equipment. The company's equipment production, casting and forming, mechanical processing, physical and chemical treatment, to assembly into machines, is fully tracked and inspected by quality testing engineers throughout the process to ensure that users receive high-quality, reliable equipment.

The company has been working hard to build the Kaibang brand for decades, always pursuing excellence, with high-quality staff, strict quality assurance system and perfect after-sales service. We warmly welcome domestic and overseas customers to visit our company for on-site inspection and guidance.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: +86 13849088788

Phone: 13849088788

E-mail: kaibangmachinery@gmail.com

Whatsapp:8613849088788

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road