News

Taking sawdust as an example, how to control the moisture content of raw materials for charcoal machine production?

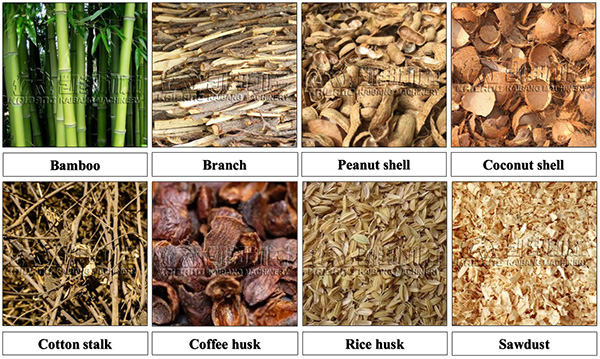

It is known that there are many raw materials for Charcoal machine equipment, such as sawdust, branches, straw, rice straw, peanut shells, tea seed shells, fruit shells, weeds, leaves, etc., which can all produce machine-made charcoal. In the process of charcoal production, the moisture control of raw materials is very critical. If the moisture is too high, it will not be pressed into shape, and if the moisture is too low, it will cause too many powder particles. So how to control this degree?

We take sawdust as an example to produce machine-made charcoal, because sawdust can fully absorb moisture, and it is not easy to freeze in winter. Therefore, manufacturers strongly recommend using sawdust raw materials as finished charcoal raw materials. How to control the moisture content of raw materials is a problem that every manufacturer and user pays attention to. For example: using sawdust as raw material, grab a handful of sawdust and count it into a ball, then loosen it to see if the raw material is fluffy. If the raw material is fluffy, it can be used directly. If it does not expand, but agglomerates, it means that the moisture content of the raw material is about 30-40%, and it can be dried before use. This is taking sawdust as an example. Of course, if you use other raw materials, if you have any questions, feel free to consult Kaibang charcoal machine equipment manufacturer. We welcome you!

RELATED NEWS

- Why is a sawdust drum dryer needed in the production of charcoal and biomass bri 2025-05-14

- How to choose the right carbonization furnace to benefit your charcoal business? 2025-04-16

- Factors affecting the price of charcoal machines 2025-03-24

- What kind of mechanism charcoal machine is environmentally friendly equipment? H 2025-02-18

- Why avoid overnight production of raw materials for charcoal making equipment? H 2025-01-10

CATEGORIES

LATEST NEWS

CONTACT US

Contact: +86 13849088788

Phone: 13849088788

E-mail: kaibangmachinery@gmail.com

Whatsapp:8613849088788

Add: 800 meters east of the intersection of Chuangye Avenue and E23 in Gongyi Industrial Agglomeration Zone, Zhengzhou City, Henan Province, north of the road